Is Puffing Up Snack Food Bags Just for Looks?

📦 Is the air just there to reduce the amount of product or cut costs?

❌ NO, NO, NO!

There’s real science behind this! 💡

🔬 The Science Behind Inflated Food Packaging

Almost all food spoilage is directly or indirectly related to oxygen.

✅ Core Solution: Isolate food from oxygen to extend shelf life

✅ How It’s Done: Fill the bag with an inert gas to displace air

⚗️ Why Nitrogen?

Nitrogen is the #1 choice for food packaging inflation. Here’s why:

🛡️ Inert Protection: Non-oxidizing, inhibits oxidation and microbial growth

💧 Moisture Barrier: Positive pressure keeps moisture out, slowing spoilage

📦 Physical Cushion: Gas buffer protects fragile snacks like chips from breakage

💰 Best Value: Inexpensive, non-toxic, odorless, and highly stable

📝 Regulatory Note:

Nitrogen is approved as a processing aid in food manufacturing

(no labeling required and no residual limits)

⚠️ Must meet national food additive safety standards

Note: CO₂ is also commonly used for food preservation

🥔 The Truth About Inflated Chip Bags

🔍 Main Purposes of Inflation:

▸ Anti-oxidation (Keeps chips crisp!)

▸ Moisture resistance

▸ Crush prevention

⚙️ Packaging Process Workflow:

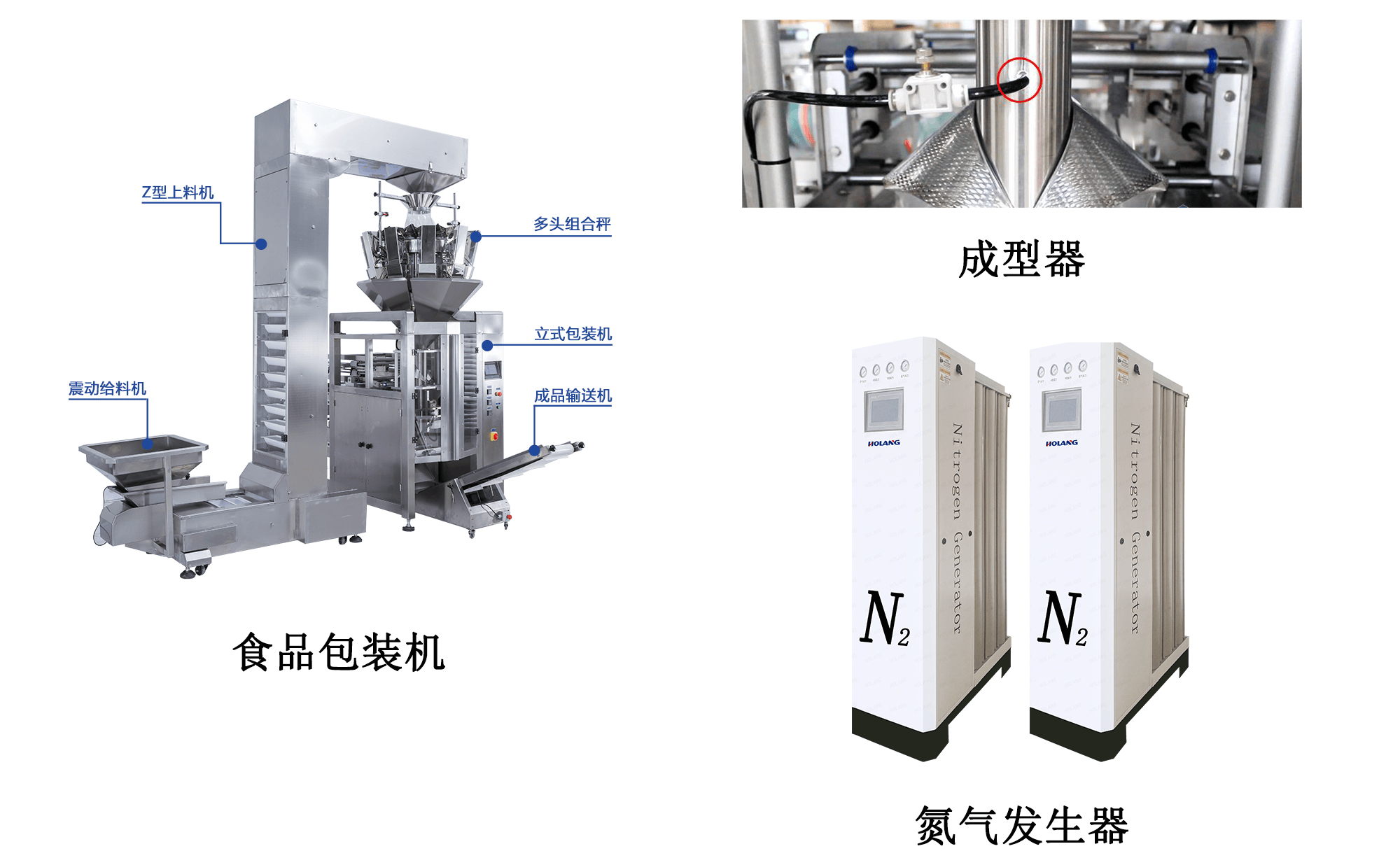

Feeder → Multi-head Weigher → Vertical Form Fill Seal Machine → Nitrogen Generator

✨ Key Step: The forming tube is equipped with a gas filling device, which is connected to the nitrogen generator for precise nitrogen infusion.

📊 Nitrogen Generator Selection Guide

🏆 Recommended Solution:

HOLANG PSA Modular Nitrogen Generator – NPL02 / NPL03

✅ Compact footprint

✅ High efficiency

✅ Specially designed for food packaging applications

Contact Us :

Phone:+86 400 0512 711

Address: No. 51 Jinsigang Road, Wuzhong District, Suzhou, China

Email: marketing@holangchina.com