JOIN US

— Unveiling the "Invisible Guardian" in the Biopharmaceutical Industry

In biopharmaceuticals, every microgram of sample viability and every milliliter of reagent stability impacts human health:

🧫 Cell Culture: Oxygen fluctuations disrupt cellular metabolism

💊 Lyophilized Formulations: Moisture residues trigger drug denaturation

🔬 Mass Spectrometry: Environmental contaminants compromise accuracy & equipment lifespan

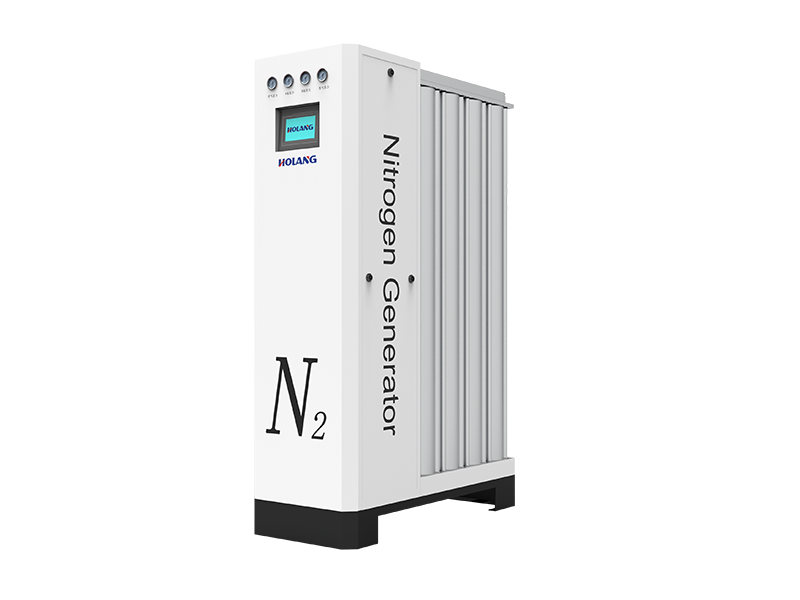

Nitrogen Generators: The Master Key to Precision:

Delivering 99.999% ultra-pure nitrogen to create an oxygen-free, anhydrous, sterile barrier across R&D, production, and storage.

1️⃣ Sterile Environment Creation

In biotechnological processes, cell culture, vaccine production, and other biopharmaceutical preparations, nitrogen is used to create an anaerobic or low-oxygen environment, protecting sensitive biological materials from oxidation while preventing microbial growth, ensuring the quality and safety of biological products.

2️⃣ Pharmaceutical Manufacturing & Packaging

During pharmaceutical production, nitrogen, as an inert gas, prevents drug components from oxidizing, protects reactors, and improves the stability and efficacy of drugs. During packaging, filling with high-purity nitrogen delays drug degradation and extends shelf life, which is particularly crucial for oxygen-sensitive drugs like vitamins and antibiotics.

3️⃣ Laboratory Operations

In pharmaceutical laboratories, nitrogen is used to clean and purge equipment, removing potential contaminants. High-purity nitrogen is also used to handle samples before gas chromatography-mass spectrometry (GC-MS) analysis, ensuring the accuracy of results.

4️⃣ Medical Device Maintenance

Some medical devices require nitrogen for cleaning, drying, or as a driving gas. Nitrogen purification systems provide stable, high-purity nitrogen to ensure the proper functioning and prolonged lifespan of medical equipment.

5️⃣ Drug Storage & Transportation

For oxygen-sensitive pharmaceutical products, such as active pharmaceutical ingredients (APIs) and other chemicals, nitrogen is used as a purging gas during packaging to prevent oxidation and degradation. During transport, nitrogen helps maintain the sterility and cleanliness of products, ensuring their stability and safety.

(Comparison Table: Red/Green Alert Style)

| Gas Cylinders | Holang Modular Generator |

|---|---|

| Purity fluctuation (85%-99.9%) | 95%-99.999% adjustable |

| Supply interruptions, gas exchange, transportation risks | 24/7 continuous flow |

| Annual maintenance costs >100,000 CNY | 55% energy saving, ROI in 3 years |

| High-pressure storage hazards | Modular design, on-site nitrogen generation, small footprint, safe and reliable |

🔬 Technical Superiority:

High-quality carbon molecular sieve intelligent regeneration system

Built-in oxygen analyzer for real-time oxygen content monitoring, ensuring continuous stable anaerobic conditions

Triple filtration system with particulate matter ≤ 0.01μm

International ISO quality certification and CE certification

"Nitrogen is not merely a gas flow—it's the invisible hand shielding life's vital spark."

Holang Technology delivers military-grade precision for medical nitrogen solutions,ensuring every breath of innovation sustains hope.

Act Now for Your Pharmaceutical-Grade Nitrogen Solution

Hotline: +86 400 0512 711