For any production manager, seeing the nitrogen purity reading drop from 99.99% to 98% is a nightmare. It means potential oxidation, product defects, and production downtime.

Is your Carbon Molecular Sieve (CMS) dead? Or is it a simple setting error?

Before you spend thousands on replacing the CMS, check these 6 key causes identified by HOLANG engineering team.

Cause 1: Overdrawing the Flow Rate (User Error)

The Problem: The most common cause is simply asking the machine to do too much. If you increase the outlet flow rate beyond the design capacity, the nitrogen doesn't have enough "residence time" in the adsorption tower.

The Result: The CMS cannot remove enough oxygen, and purity drops immediately.

🔧 The Fix: Check your flowmeter. Is it higher than the rated capacity? Reduce the flow to the design value and see if purity recovers.

💡 The HOLANG Advantage:

HOLANG systems feature a "Flow-Purity Interlock". If the flow exceeds the limit, the system alerts you automatically, preventing accidental purity drops.

Cause 2: Oil & Water Contamination (The "CMS Killer")

The Problem: Carbon Molecular Sieve is extremely sensitive to oil. If your air compressor's filters fail, oil vapor enters the nitrogen generator.

The Result: Oil "poisons" the CMS micropores permanently. Once poisoned, the CMS cannot be regenerated and must be replaced.

🔧 The Fix: Check your pre-filters immediately. Are they saturated? If you find oil inside the adsorption tower, you likely need a full CMS replacement.

💡 The HOLANG Advantage:

We use 4-Stage Heavy Duty Filtration (Active Carbon + Coalescing) as standard on all NPL series to guarantee zero oil entry, extending CMS life to 10+ years.

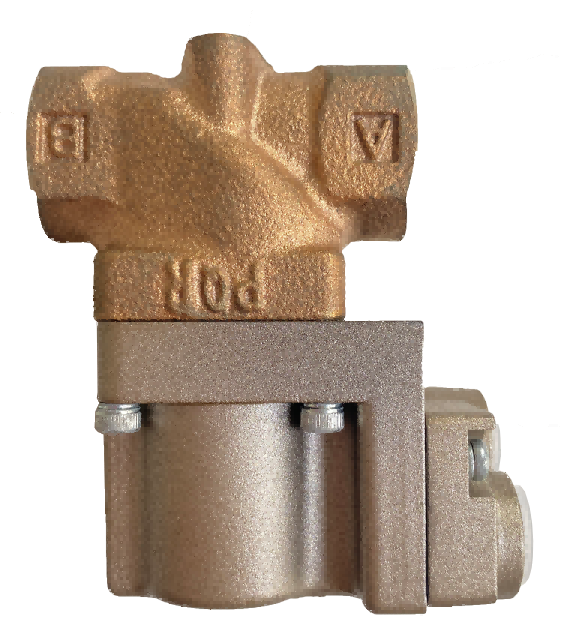

Cause 3: Solenoid/Pneumatic Valve Leakage

The Problem: PSA technology relies on rapid pressure swings. If a valve seal wears out and leaks, the tower cannot build up enough pressure to separate oxygen.

The Result: You will hear a hissing sound, or see the pressure gauge failing to reach the peak value.

🔧 The Fix: Perform a "Soap Water Test" on valve connections. Replace the seal kits if bubbles appear.

💡 The HOLANG Advantage:

We use German/Japan Brand Valves (Bürkert/SMC) rated for 2 million cycles, significantly reducing the risk of mechanical leakage compared to generic valves.

Cause 4: Carbon Molecular Sieve (CMS) Pulverization

The Problem: In cheaply designed generators, the CMS is not tightly pressed. The constant pressure impact causes the loose carbon beads to rub against each other, turning them into dust (powder).

The Result: Air channels are blocked, and efficiency plummets. You might see black dust coming out of the exhaust muffler.

🔧 The Fix: This is a major failure. You need to clean the vessel and refill with new CMS.

💡 The HOLANG Advantage:

HOLANG uses a unique "Snowstorm Filling" + "Spring Compression" technology. This ensures the CMS is packed tight and cannot move, preventing pulverization permanently.

Cause 5: Temperature Issues

The Problem: Adsorption physics is temperature-dependent.

-

Too Hot (>45°C): CMS adsorption capacity drops.

-

Too Cold (<5°C): Water vapor may freeze and block pipes.

🔧 The Fix: Ensure your compressor room is well-ventilated. If the inlet air temperature is too high, check your refrigerated air dryer.

Cause 6: The "False Alarm" (Oxygen Analyzer Failure)

The Problem: Sometimes, the machine is fine, but the Sensor is lying. Electrochemical oxygen sensors are consumables and age over time (drift).

The Result: The screen shows "98%", but your portable tester shows "99.99%".

🔧 The Fix: Calibrate your analyzer with standard gas or compare it with a handheld unit. Don't panic until you verify the sensor!

🚑 Need a Professional Diagnosis?

If you have checked the above and the purity is still low, don't blindly replace the CMS. It might be a solvable system error.

Let HOLANG Engineers help you troubleshoot for FREE