Nitrogen Generators in the Laser Cutting Industry: Key Roles, Applications, and Advantages

——Providing an economical, efficient, safe, and reliable inert gas source, nitrogen generators enhance cutting quality, support special materials, and protect valuable equipment.

Nitrogen generators play a crucial role in the laser cutting industry by providing an economical, efficient, safe, and reliable source of inert gas. Their primary functions include improving cutting quality, processing specific materials, and protecting equipment. Below are the core applications and advantages of nitrogen generators:

I. Core Application Scenarios

Cutting High-Metal Materials (e.g., Stainless Steel, Aluminum Alloys):

- Prevents Oxidation: Nitrogen, as an inert gas, creates a protective atmosphere in the cutting zone, isolating oxygen and preventing oxidation of metals at high temperatures. This avoids the formation of oxide layers (blackening, bluing) on the cut edges.

- Enhances Cutting Quality: Oxidation-free cut edges are bright, clean, and free of slag, significantly improving the appearance and accuracy of the product. This is especially important for items that do not require secondary processing (e.g., grinding, polishing), saving time and costs.

- Increases Cutting Speed: Using nitrogen typically enables faster cutting speeds compared to oxygen or other gases, especially when cutting thin stainless steel and aluminum alloys.

Example of Galvanized Steel: Galvanized steel is protected by a zinc coating, making it resistant to rust over time. There are three cutting methods for galvanized steel: air cutting, oxygen cutting, and nitrogen cutting. Each has its advantages and disadvantages:

- Air Cutting: The advantage is a low processing cost, considering only laser and air compressor electricity costs. However, air cutting produces burrs on the bottom edge of the cut, and secondary processing like deburring is required, which increases the production cycle. Additionally, air cutting often results in blackened cut surfaces, affecting the product’s quality.

- Oxygen Cutting: This traditional and standard cutting method is widely used in carbon steel sheet metal processing. The main advantage is that it doesn’t require frequent switching of auxiliary gases, making it easy to manage in a factory setting. However, it leaves an oxide layer on the cut surface, which can cause welding issues when used for galvanized sheets.

- Nitrogen Cutting: Nitrogen cutting works by melting the material with laser energy and using nitrogen to blow out the cut slot. Unlike oxygen, nitrogen doesn’t burn the material but protects the cut surface, preventing oxidation. The cutting process is stable and even, resulting in high-quality cuts with smooth, delicate edges and no oxide layer. Nitrogen cutting is ideal for low-melting-point materials like aluminum and brass, and it can be used for oxidation-free cutting of stainless steel.

Cutting Special Materials (e.g., Titanium Alloys):Titanium alloys tend to react with oxygen and nitrogen at high temperatures. However, using high-purity nitrogen (typically 99.999%) can significantly reduce these reactions, leading to better cutting performance and reduced brittleness risks.

- Protecting Lasers and Optical Lenses:Prevents Lens Contamination: Molten metal splashes during cutting can form oxide smoke when exposed to oxygen. These fumes can adhere to focusing lenses and protective mirrors, reducing transparency, affecting cutting performance, and potentially damaging expensive lenses. Nitrogen atmospheres reduce the formation of oxide smoke, protecting optical systems and extending lens lifespan, while reducing downtime for cleaning and maintenance.

- Protects Laser Output Windows: In some laser structures, nitrogen purging can protect the laser output window from contamination.

II. Advantages of Nitrogen Generators Compared to Traditional Gas Supply Methods (Liquid Nitrogen, High-Pressure Cylinders)

- Lower Operating Costs: While there is an initial investment in equipment, nitrogen generators primarily incur electricity costs over time. There are no transportation fees for liquid nitrogen tanks or rental, deposit, and replacement service fees for high-pressure cylinders. The investment payback period is usually between 6-12 months.

- Higher Safety: The risks associated with high-pressure cylinders, such as tipping over or explosion, are eliminated. There are no concerns regarding cryogenic burns or asphyxiation when handling liquid nitrogen, and the safety risks related to gas transportation are significantly reduced.

- Continuous and Stable Supply: Nitrogen generators provide continuous gas supply, supporting 24/7 production schedules without external supply time limitations.

- On-Demand Production: Nitrogen generators can produce nitrogen in real-time according to the specific needs of laser cutting machines, eliminating the risk of running out of gas. There are no worries about running out of the last gas cylinder, delayed liquid nitrogen delivery, or suppliers being unavailable during holidays.

- Stable Pressure and Flow: Advanced generator systems provide stable pressure and flow rates of nitrogen, ensuring consistency in the cutting process.

- Environmental Benefits: On-site nitrogen generation reduces carbon emissions associated with gas production and transportation (e.g., delivery vehicles, liquid nitrogen production energy consumption). It is more energy-efficient and environmentally friendly.

III. Key Factors to Consider When Choosing a Nitrogen Generator

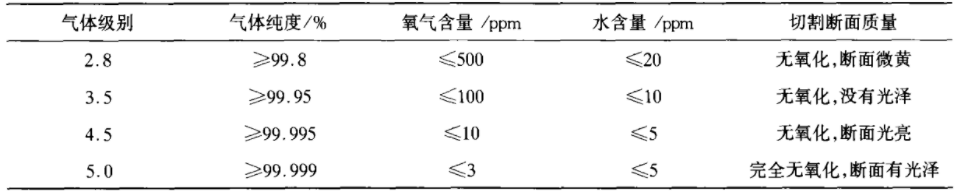

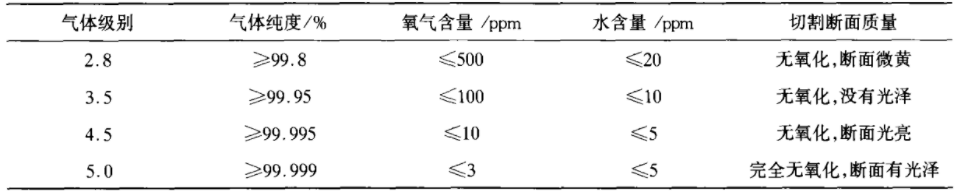

Nitrogen Purity:

Laser cutting of stainless steel and aluminum alloys typically requires nitrogen purity of 99.5% or higher. Insufficient purity can lead to oxidation or yellowing of the cut edges. For special materials like titanium alloys, ultra-high purity nitrogen (99.999%) may be required.

Technology Options:

Pressure Swing Adsorption (PSA): Economical and efficient, it can consistently produce nitrogen with purities ranging from 95% to 99.999%, covering a wide flow range, making it the mainstream choice in the laser cutting industry.

Membrane Separation: This technology is simpler in structure and requires less maintenance. However, it typically offers lower purity (95%–99.5%), and the purity may vary with flow rate and pressure. It is more suitable for applications with less stringent purity requirements.

Flow Rate:

The flow rate must meet the peak gas consumption of the laser cutting machine during maximum power operation and when cutting the thickest materials. The required flow rate should be accurately calculated based on the laser power, nozzle size, material type, and thickness, with some margin for safety.

Pressure:

In actual production, gas pressure and nozzle size determine the roughness of the cut edge. Increasing gas pressure helps with slag removal but excessive pressure may increase roughness. Nitrogen is not involved in combustion, and it is used to blow off molten material at relatively low temperatures, requiring a high gas pressure of 10-14 bar. A larger nozzle diameter is required to ensure sufficient flow rate.

Reliability and Brand Service:

It is essential to select a reliable supplier with mature technology and the ability to provide timely local service and spare parts. This ensures the long-term stable operation of the equipment and reduces downtime losses.

IV. Conclusion

Nitrogen generators have become a standard configuration and core competitive advantage in the modern laser cutting industry, particularly for high-precision and high-quality cutting of stainless steel and aluminum alloys. By providing continuous, stable, and high-purity nitrogen, they significantly improve cutting edge smoothness, eliminate oxidation layers, increase cutting speed and efficiency, protect expensive laser optics, and, most importantly, reduce long-term gas costs, enhance production flexibility, and improve safety. For laser processing businesses, investing in a nitrogen generator of suitable specifications is often a wise and necessary decision.

Recommended model: NMA/NPA/NPL