JOIN US

——High-purity nitrogen technology helps modern food industries improve preservation, ensure food safety, and enhance brand competitiveness.

In the modern food industry, shelf life, freshness, and product safety are critical factors that directly influence brand competitiveness. As a result, more food manufacturers are turning to on-site nitrogen generation systems to optimize packaging processes and reduce operational risks.

In this article, we’ll explore the benefits of nitrogen in food packaging, common use cases, and why HOLANG nitrogen generators are rapidly becoming the preferred solution in the sector.

Why Use Nitrogen in Food Packaging?

Oxygen is a primary cause of food degradation. When exposed to air, many products undergo oxidation, bacterial growth, flavor loss, and spoilage. Using high-purity nitrogen (typically 99.9% to 99.999%) in packaging can:

Product CategoryPackaging TechniqueNitrogen BenefitSnack FoodsNitrogen flushingPrevent breakage and oxidationFresh Meats & SeafoodMAP (Modified Atmosphere Packaging)Inhibit bacteria and extend freshnessCoffee, Tea, SpicesNitrogen purgingMaintain aroma and prevent moisture absorptionBaked GoodsNitrogen backfillingDelay mold growth and preserve softness

Problems with Traditional Nitrogen Supply:

Many factories still rely on liquid nitrogen or gas cylinders, which pose several issues:

Cost Comparison: Why On-Site Nitrogen Generation Wins:

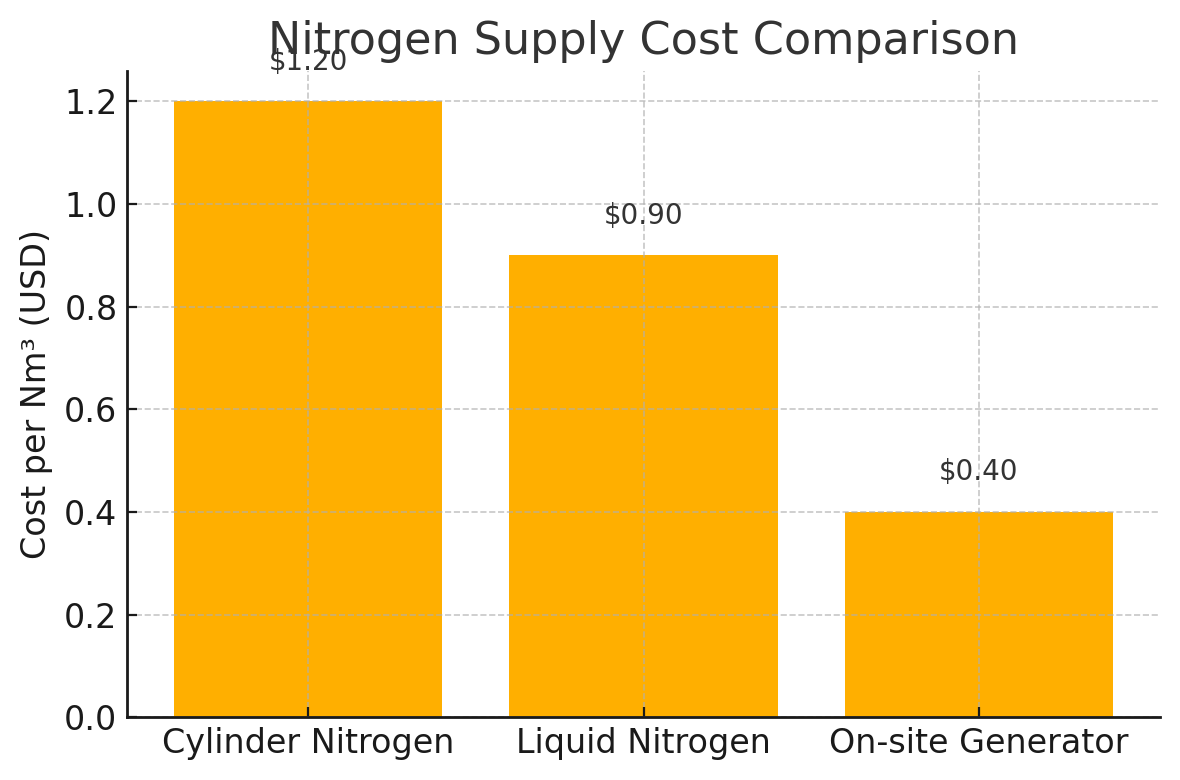

One of the key advantages of installing a nitrogen generator on-site is the dramatic reduction in gas supply costs. Below is a comparison of nitrogen cost per Nm³ using different supply methods:

Figure: On-site nitrogen generation offers the lowest cost per Nm³, ideal for high-consumption packaging lines.

As seen above, on-site nitrogen generators can reduce cost per Nm³ by over 60% compared to bottled or liquid nitrogen. This becomes especially critical for food factories running 24/7 production lines.

Why HOLANG Nitrogen Generators?

HOLANG offers industry-proven nitrogen systems tailored for food packaging, including PSA systems (NPL series) and modular containerized solutions (NitroMod).

Real-World Case Study: Snack Manufacturer in Southeast Asia

Client: Leading snack food brand producing potato chips and puffed snacks

Location: Southeast Asia

Challenge: High cost from bottled nitrogen and frequent supply interruptions

Solution: HOLANG NPL40 PSA Nitrogen Generator + integrated air system

Outcome:

This case illustrates how in-house nitrogen systems are not just a cost-saving measure but also a quality assurance investment.

The Shift Towards Sustainability and Autonomy

With increasing ESG and sustainability requirements, on-site nitrogen generation aligns with food factories’ green transition goals:

Conclusion: Invest in Long-Term Efficiency

Nitrogen is no longer just a packaging supplement—it's a strategic asset in food manufacturing. By investing in HOLANG nitrogen generators, businesses can ensure product quality, cut recurring costs, and gain independence from volatile gas markets.