Why 3D Printing Needs an Oxygen-Free Environment: Nitrogen Generators for Precision Manufacturing

——How Nitrogen Generators Unlock the High-Precision Code of 3D Printing

3D printing, also known as Additive Manufacturing (AM), is a technology that creates solid parts through layer-by-layer material addition, based on 3D CAD data.

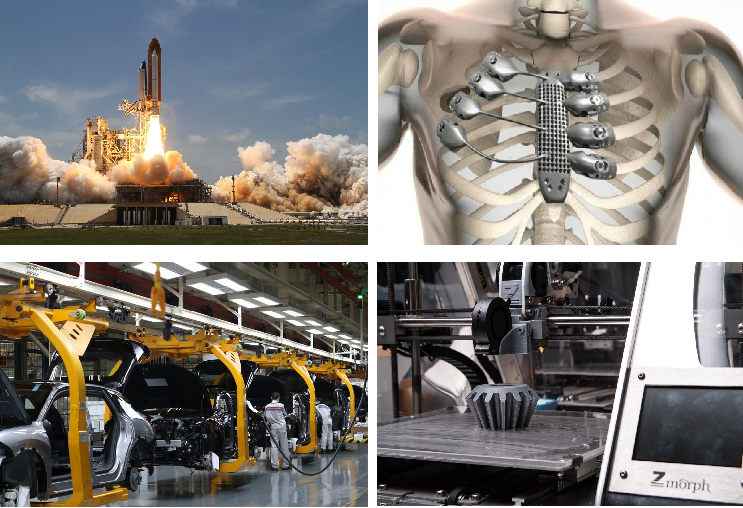

Working Principle of 3D Printing

The working principle of a 3D printer is "layer-by-layer manufacturing," where each layer is added to build the object.

Main Components of a 3D Printer

- Print Bed: Supports and holds the object being printed.

- Print Head: Responsible for heating and extruding the printing material, building the object layer by layer.

- Guide System: Ensures precise movement of the print head and bed in three-dimensional space.

- Control System: Includes electronic and software controls to interpret digital models and direct printer movements.

- Motors and Transmission Systems: Control the guide system, raising and lowering the print bed, and moving the print head.

- Printing Materials: These include plastic filaments, resins, metal powders, and others, varying according to the printing technology.

Applications of 3D Printing

On one hand, 3D printing can directly convert digital models into physical objects, eliminating the mold-making process and drastically reducing production time. On the other hand, it allows for personalized designs and the printing of complex shapes and structures, enabling precise material usage and reducing costs and material waste.

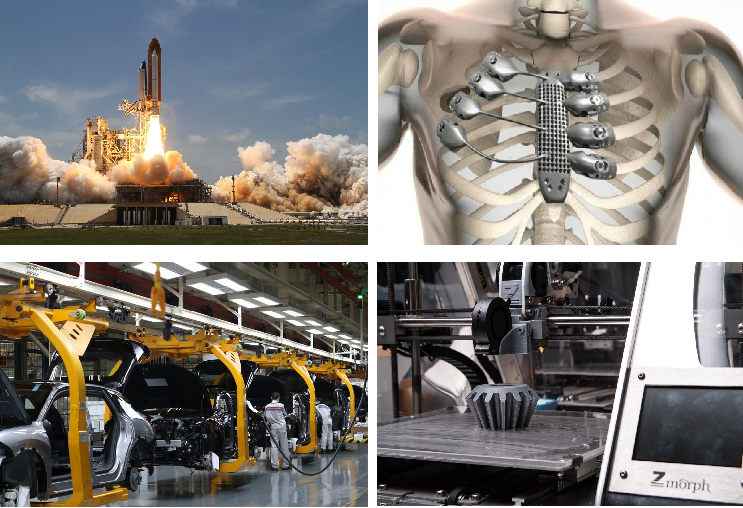

Due to its high precision, flexibility, material utilization, and superior performance, 3D printing is widely used in aerospace, medical, automotive, and manufacturing industries.

- Aerospace: Used for manufacturing complex and highly precise metal parts, such as engine blades, gears, and brackets, which are crucial to the performance and safety of aircraft.

- Medical Field: Used for creating personalized medical devices and implants, such as 3D-printed liver models, dental implants, joint replacements, and surgical guides, with excellent biocompatibility.

- Automotive Industry: Used for manufacturing lightweight automotive parts like engine brackets, brake systems, and fuel injection systems, which help improve vehicle performance and fuel efficiency.

- Manufacturing Industry: Used for rapid prototyping, mold manufacturing, and direct production of parts, increasing production efficiency and flexibility.

Nitrogen Gas in 3D Printing

Nitrogen gas plays a critical role in creating an inert atmosphere to prevent material oxidation and improve print quality. However, not all 3D printing processes require nitrogen gas.

Applications of Nitrogen Gas in 3D Printing

- Metal 3D Printing: For processes like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), nitrogen gas prevents oxidation of metals like titanium and aluminum alloys, improving the print quality.

- Thermoplastic 3D Printing: In Selective Laser Sintering (SLS), nitrogen gas is used to control temperature and oxygen levels, preventing overheating or oxidation of the material.

- High-temperature Materials: Nitrogen gas helps control temperature, preventing overheating, oxidation, or other adverse reactions in high-temperature materials.

Nitrogen Gas Generator Specifications for 3D Printing

The requirements for nitrogen gas generators in 3D printing include high purity, stability, compactness, low noise, low cost, and adjustability.

- High Purity: The purity of nitrogen gas is crucial, as it directly impacts the purity of the printing material and the final product's quality. Different materials have different nitrogen purity requirements; for example, nylon requires 99% purity, while metals require 99.99%.

- Flow Configuration: Nitrogen generators for 3D printing generally need to be equipped with a storage tank. Nitrogen is used for large-scale cleaning and regular operation. Large-scale cleaning requires high flow rates, typically around 20L/min, to quickly reduce the oxygen content in the 3D printing workspace. Regular use requires a lower flow rate. For example, Haolang nitrogen generators, such as the NPL02 or NPL03, are suitable for this purpose.

- Stability: 3D printing can be a lengthy process, so nitrogen gas purity and quality must remain consistent throughout the printing process. Therefore, the nitrogen generator must be stable and reliable, delivering high-quality nitrogen regardless of time or external factors.

- Compactness: To minimize impact on factory operations, nitrogen generators should be compact and quiet, taking up minimal space and operating quietly to reduce disruption to the workspace and protect workers' health.

- Low Noise and Low Cost: The operation of nitrogen generators should be relatively quiet to maintain a peaceful working environment, and the cost of obtaining nitrogen should be minimized to achieve cost savings.

- Adjustability: Different 3D printing devices may have varying gas requirements, so nitrogen generators should offer adjustable flow rates and purity settings to accommodate the specific needs of different 3D printers, providing safe, efficient, and energy-saving nitrogen supply.

Recommended model:NMA/NPA/NPL