The debate between Pressure Swing Adsorption (PSA) and Membrane nitrogen generation technologies has been ongoing for decades. However, viewing them as direct competitors often misses the bigger picture.

Instead of asking "Which technology is better?", a more productive approach is to ask: "Which technology fits my specific industrial scenario?"

🚀 Quick Decision: PSA or Membrane?

|

Feature |

PSA Technology |

Membrane Technology |

|---|---|---|

|

Best For |

Electronics, Laser Cutting, Food Packaging |

Oil & Gas, Mining, Mobile Applications |

|

Purity Range |

Ultra-High (99.9% to 99.9995%) |

Standard (95% to 99.9%) |

|

Key Advantage |

High Purity & Stability |

Continuous Flow & Low Maintenance |

|

Our Solution |

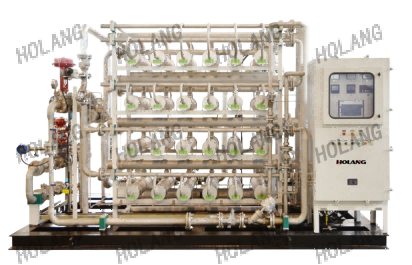

Explore HOLANG Membrane Systems → |

Phase 1: The Era of "Continuous Supply" (1990s–2000s)

In the early stages, industries like Petrochemicals and Oil & Gas drove the demand for nitrogen generation. For these sectors, the priority was not ultra-high purity, but uninterrupted reliability in harsh environments.

Membrane technology became the dominant choice during this era because:

-

It has no moving parts (valves).

-

It offers instant startup and continuous flow.

-

It requires minimal maintenance in remote locations.

💡 Is this your requirement?

If your operation requires rugged, mobile, or zero-maintenance nitrogen supply (e.g., for purging or tank blanketing), Membrane technology remains the superior choice today.

Phase 2: The Rise of "High Purity" Manufacturing (2000s–2015)

-3RBajwIs.jpg)

As global manufacturing shifted towards higher precision, the limitations of membrane technology (mainly purity limits) became apparent. The boom in SMT Electronics, Laser Cutting, and Heat Treatment created a new demand: High Purity (up to 99.999%).

This ushered in the golden age of PSA (Pressure Swing Adsorption).

Unlike membranes, PSA technology utilizes Carbon Molecular Sieves (CMS) to achieve:

-

Extreme Purity: Capable of reaching 99.9995% purity effortlessly.

-

Efficiency: Lower air-to-nitrogen ratios at high purity levels.

-

Control: Precise management of dew point and oxygen content.

💡 The Modern Standard:

For today's electronics and advanced manufacturing facilities, PSA is the industry standard. HOLANG’s [NPL Series PSA Generators]are specifically engineered to meet these strict IPC standards for soldering and packaging.

Phase 3: Scenario-Based Selection (2015–Present)

Today, the "PSA vs Membrane" battle has evolved into a scenario-based selection process. It is no longer about technology superiority, but about application fit.

-

Choose PSA when your process is sensitive to Oxygen (ppm level), such as in Lithium Battery production or 3D Metal Printing.

-

Choose Membrane when you need simple, robust nitrogen air for fire prevention or general purging.

Why PSA has Grown Faster Recently?

You may have noticed a surge in PSA adoption over the last decade. This is not because PSA "defeated" Membrane, but because the industrial structure has changed:

-

The explosion of Electronics & Semiconductor manufacturing.

-

The rise of the EV Battery industry.

-

The shift from liquid nitrogen purchasing to on-site gas generation.

These high-growth industries naturally favor the characteristics of PSA technology.

Future Landscape: It’s About the System

The future of nitrogen generation lies in intelligent system integration.

-

Modular Architecture: For easy expansion.

-

Digital Operation: For predictive maintenance.

-

Hybrid Solutions: Large complexes may use both PSA (for core process) and Membrane (for general utility) to optimize costs.

Summary Comparison Table:

|

Feature |

PSA (Pressure Swing Adsorption) |

Membrane |

|---|---|---|

|

Purity |

High (95% - 99.9995%) |

Standard (95% - 99.9%) |

|

Pressure |

Moderate (6-8 bar typically) |

High (can handle high inlet pressure) |

|

Maintenance |

Regular valve maintenance required |

Extremely low (no moving parts) |

|

Efficiency |

Higher efficiency at high purities |

Higher efficiency at low purities |

|

Ideal For |

Electronics, Metal, Food, Lab |

Oil&Gas, Marine, Mining, Purging |

🎯 Ready to optimize your Nitrogen Supply?

Choosing between PSA and Membrane can be tricky without detailed flow and purity calculations. Don't risk your production quality on a guess.

Let our engineers help you calculate the ROI:

-

✅ Free analysis of your current gas consumption.

-

✅ Comparison of PSA vs Membrane efficiency for your specific factory.

-

✅ A customized proposal within 24 hours.