A Pressure Swing Adsorption (PSA) nitrogen generator is a critical asset for industrial production. To ensure specific nitrogen purity (e.g., 99.999%) and extend the equipment's lifespan, a disciplined maintenance routine is non-negotiable.

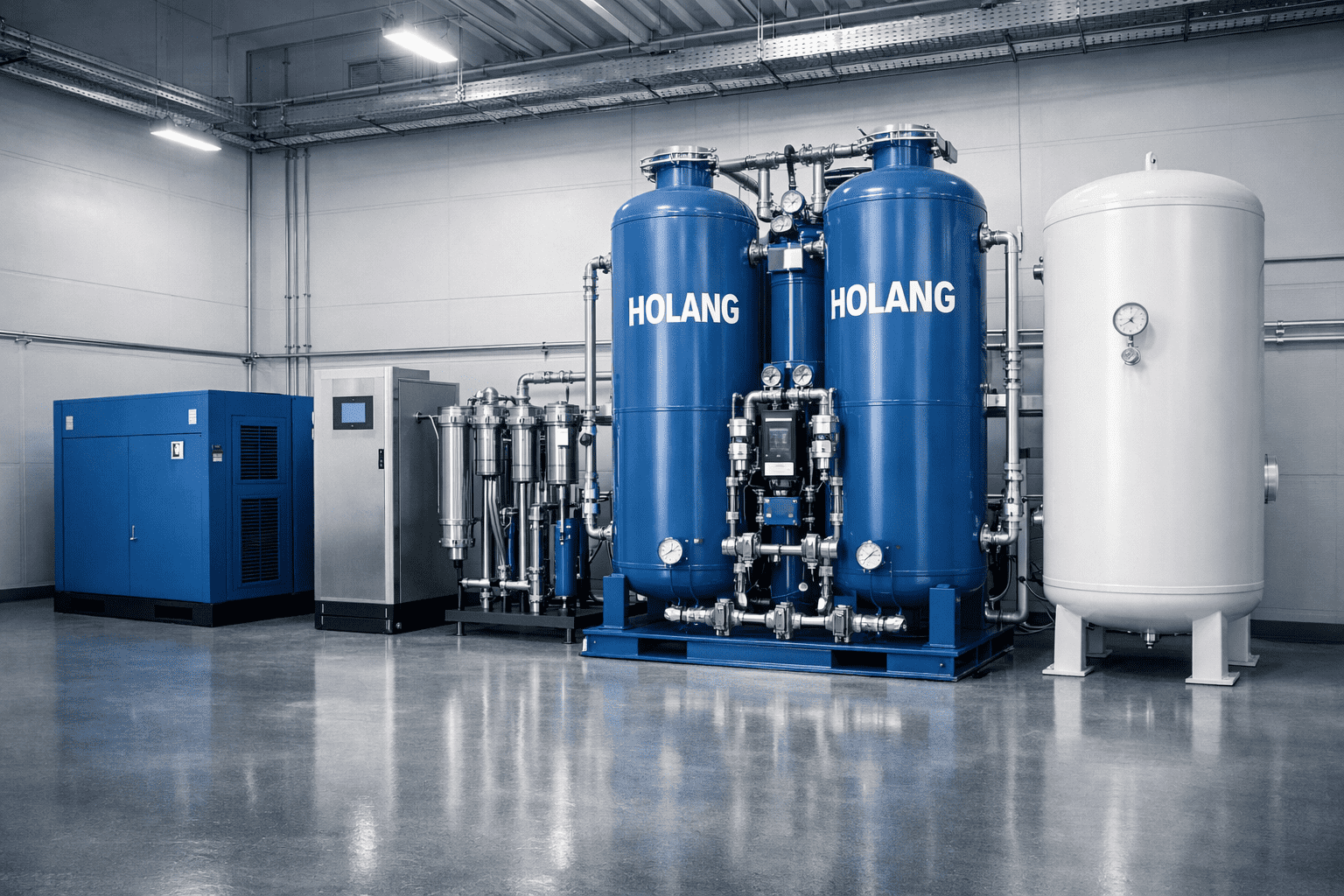

Many system failures are not caused by quality issues but by the neglect of daily maintenance. At Holang, we believe that proactive care is better than costly repairs. This guide outlines the standard maintenance procedures for the core components of your nitrogen generation system: the Air Compressor, Refrigerated Dryer, Filters, and the Nitrogen Generator itself.

1. Air Compressor System Maintenance

The air compressor provides the raw power for the entire system. Its health directly impacts the efficiency of nitrogen production.

-

Ventilation is Key: Ensure the compressor room is well-ventilated. High ambient temperatures can cause the compressor to overheat and shut down.

-

Oil Level Check: Check the oil level daily. If the oil level is low, top it up immediately to prevent mechanical seizure.

-

Radiator Cleaning: Dust accumulation on the radiator affects heat dissipation. Clean the radiator fins regularly with compressed air (blowing from inside out).

-

External Factors: We recommended using an independent air source for the nitrogen device whenever possible to avoid pressure fluctuations from other equipment.

2. Refrigerated Air Dryer Maintenance

The refrigerated dryer removes moisture from the compressed air. Moisture is the number one enemy of the Carbon Molecular Sieve (CMS) inside your nitrogen generator.

-

Check the Auto-Drain: The automatic drain is the most critical component here. Inspect it daily to ensure it is discharging water properly. A clogged drain will send water directly into your nitrogen generator, potentially ruining the CMS.

-

Monitor Pressure: Ensure the refrigerant pressure gauge is within the normal range (usually clearly marked in green).

-

Clean the Condenser: Just like the compressor, keep the dryer's condenser fins clean and free of dust.

3. Filters and Activated Carbon Maintenance

Filters are the defense line that protects the expensive Carbon Molecular Sieve from oil and water vapor.

-

Filter Drains: Similar to the dryer, check the automatic drains on all filters daily.

-

Element Replacement: The filter element is a consumable. Do not try to clean and reuse it indefinitely.

-

Rule of Thumb: Replace filter elements every 4,000 to 6,000 hours of operation, or immediately if the differential pressure indicator turns red.

-

-

Activated Carbon: The activated carbon tower removes residual oil vapor. The carbon itself should generally be replaced once a year (depending on usage) to prevent oil poisoning of the CMS.

4. Nitrogen Generator & Analyzer Maintenance

This is the core of your system.

-

Solenoid Valves: Listen for the rhythmic clicking sound of the valves. They should operate smoothly without sticking.

-

Mufflers: If the exhaust noise becomes unusually loud or if you see dust blowing out, the muffler may be clogged or the CMS might be pulverized (a sign of serious issues).

-

Oxygen Analyzer: The analyzer ensures your nitrogen purity meets the standard. The oxygen sensor (fuel cell) typically has a lifespan of 1-2 years. If the reading drifts or becomes unstable, calibrate it or replace the sensor.

📅 Summary: Maintenance Schedule Checklist

Use this quick reference table for your maintenance team.

| Frequency | Component | Action Item |

|---|---|---|

| Daily | Air Compressor | Check oil level; Check exhaust temperature. |

| Daily | Refrigerated Dryer | Verify auto-drain is discharging water. (Critical) |

| Daily | Filters | Check differential pressure gauges; Check drain valves. |

| Daily | Nitrogen Generator | Record nitrogen purity, flow rate, and pressure. |

| Weekly | Whole System | Clean radiators/coolers; Inspect for air leaks. |

| Annually | Analyzers | Calibrate Oxygen/Nitrogen analyzer sensors. |

| Every 4000h | Filters | Replace all filter elements. |

Need Professional Support?

Proper maintenance ensures your Holang Nitrogen Generator runs efficiently for years. If you are unsure about how to replace a filter or if your system is showing an error alarm, do not hesitate to contact us.

-

Explore our products: View Holang Nitrogen Generators

-

Contact Support: Get Technical Help