Last week, two representatives from an electronics manufacturing company in India visited the Suzhou factory to conduct an on-site review and technical discussion on modular nitrogen generation systems.

The visiting representatives serve as a Technical Engineer and a Procurement Supervisor, responsible for process optimization, equipment selection, and capacity planning for their electronic production lines.

In recent years, India’s electronics manufacturing sector has expanded rapidly under policy support, driving increased demand for stable nitrogen supply across various production processes. Whether in component processing, electronic assembly, or surface-mount operations, stable inert protection is essential. However, most nitrogen systems used locally still rely on traditional designs, which offer limited scalability, lower energy efficiency, and higher maintenance difficulty.

While researching solutions for long-term production upgrades, the visiting team learned about modular nitrogen generation technology and its engineering advantages through the company website, which led to further interest in conducting an in-depth evaluation.

Following multiple rounds of English email communication on system compatibility, operating conditions, maintenance models, and expansion strategies, the company decided to send technical and procurement personnel to Suzhou for an on-site assessment.

1. Technical Briefing 📘

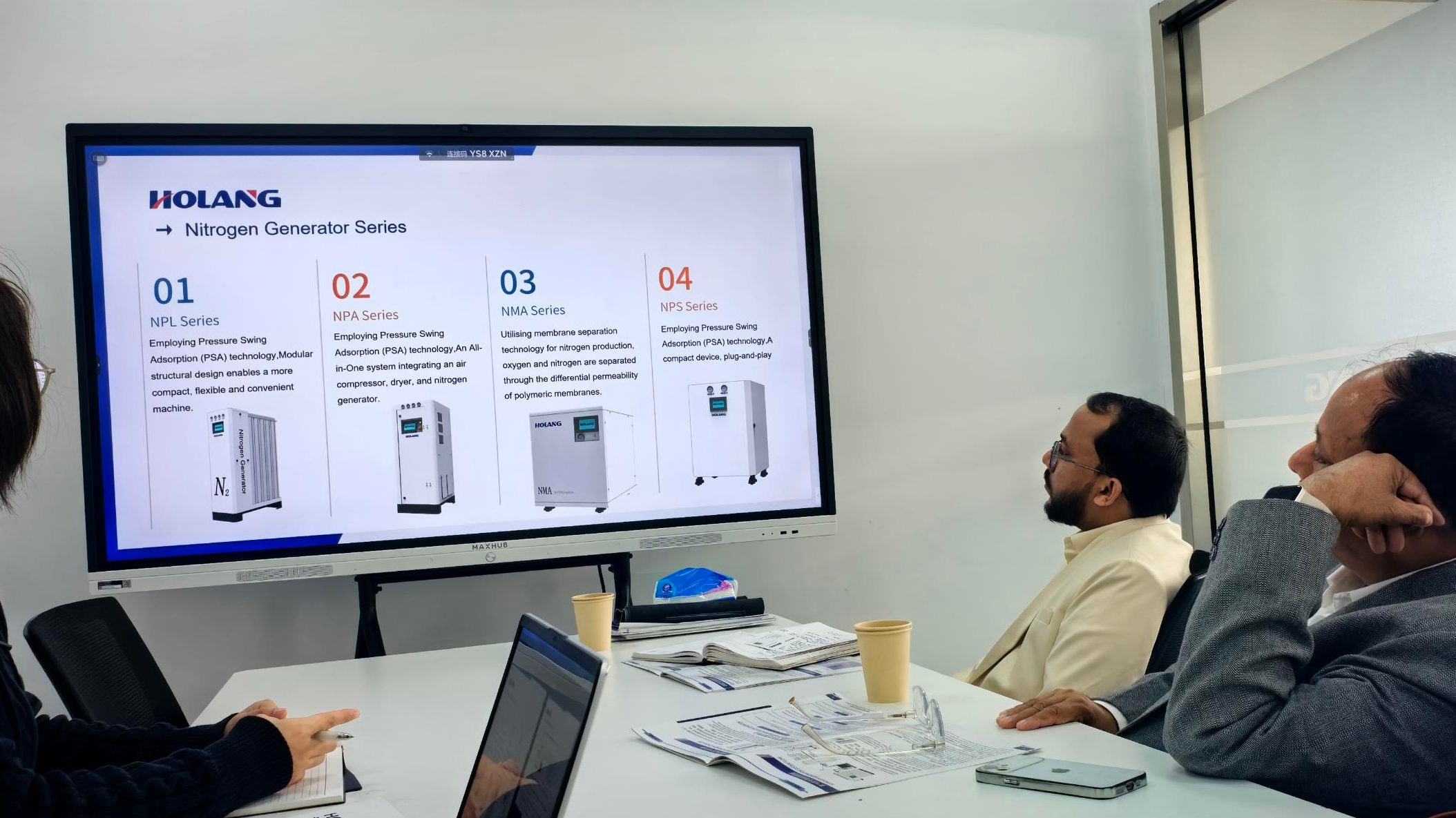

On the day of the visit, the technical team provided a comprehensive overview of the modular PSA nitrogen generation system, covering:

-

Module structure composition: including adsorption units, piping assemblies, and valve control logic.

-

Capacity expansion and load distribution: how additional modules are paralleled to increase output without disrupting existing operation.

-

Stability under varying operating conditions: purity fluctuation patterns, switching rhythm control, and adsorbent behavior.

-

Suitability for electronics manufacturing: especially purity stability requirements for reflow soldering and inert-protection processes.

This session helped the visitors build a clear engineering framework for understanding modular systems and differentiating them from conventional tower-type nitrogen generators.

2. Factory Tour 🏭

After the technical briefing, the visitors entered the production workshop for a full facility tour.

The visit covered several key areas:

-

Assembly stations: observing module construction, component arrangement, and standardized assembly procedures.

-

Piping and core components area: including valve configuration, pressure regulation design, switching control logic, and component selection rationale.

-

Factory testing section: reviewing testing workflows for pressure, purity, flow rate, and data documentation.

During the tour, the visiting engineers raised numerous technical questions based on their production scenarios, focusing on:

-

Purity stability during long-term continuous operation

-

Reliability and repeatability of module switching, including wear factors and switching frequency

-

Load balancing strategies after system expansion

-

Feasibility of maintenance by local technical teams

-

Nitrogen quality under temperature and humidity fluctuations in sensitive processes

These concerns align closely with their upcoming production line upgrade and reflect broader challenges faced by electronics manufacturers in India during equipment modernization.

3. Engineering Discussion ⚙️

In the module display area, deeper engineering discussions were held, covering topics such as:

-

Lifecycle management of core adsorption modules

-

Valve switching logic and system response under dynamic operating conditions

-

Pressure balancing and performance consistency in multi-module parallel operation

-

Maintenance checkpoints, consumable cycle predictions, and risk control

-

Long-term adsorbent behavior and efficiency stability

-

System suitability for continuous vs. intermittent production modes

Through hands-on explanation using actual equipment, the team helped the visitors evaluate system feasibility based on engineering facts rather than documentation alone.

4. Cooperation Progress 📑

After the visit, the representatives confirmed that the modular nitrogen system would be included in their internal evaluation for production line upgrades. Preparations have begun for process parameters and layout requirements needed for the next phase of review.

Current discussions between both sides include application scenarios, capacity configuration, expansion planning, and production layout integration.

The visiting company noted that the system’s scalability, maintenance path, and stable operation characteristics align well with their planned production expansion over the next two to three years.

Conclusion

This visit represents a typical case of overseas electronics manufacturers evaluating modular nitrogen technology as part of production line modernization.

As global electronics manufacturing continues to grow, stable, maintainable, and scalable on-site nitrogen generation solutions are becoming essential infrastructure. The engineering reproducibility and long-term operational stability of modular nitrogen systems are expected to support production upgrades across more regions in the future.