Every industrial customer wants to know the same thing: How long will a nitrogen generator last? The answer depends on the separation process used inside the system. The two most common technologies are PSA (Pressure Swing Adsorption) and Membrane Separation.

Both are proven nitrogen generation systems that use compressed air, but they achieve nitrogen in very different ways. The choice affects the purity level, flow rate, energy use, and most importantly, lifespan. This guide explains how each system works, the role of air compressors, the difference between PSA and membrane nitrogen, and what industries benefit most.

PSA Nitrogen Generators Explained:

A PSA nitrogen generator relies on carbon molecular sieve (CMS) material to separate oxygen and nitrogen molecules from feed air.

-

Step 1: Feed air preparation – Air compressors deliver pressurized air. Filters remove dust, oil, and water vapors.

-

Step 2: Adsorption – Air enters a tower filled with CMS. At high pressure, oxygen molecules attach to the sieve.

-

Step 3: Separation – Nitrogen molecules remain in the gas stream, flowing out as product gas.

-

Step 4: Tower switching – The system cycles between two towers, ensuring continuous nitrogen generation.

Purity level: 95% to 99.999%.

Flow rate: Flexible, from small labs to large industrial demand.

Lifespan: Typically 5–8 years. With clean compressed air and regular filter replacement, CMS material lasts longer.

Best industries: Electronics production, pharmaceuticals, chemical plants, metal heat treatment, 3D printing, and other high-purity applications.

Membrane Nitrogen Generators Explained:

A membrane nitrogen generator works on a different principle using membrane technology.

-

Step 1: Feed air passes through hollow fiber membranes.

-

Step 2: Gas separation happens because different molecules move at different speeds.

-

Oxygen, carbon dioxide, and water vapors permeate through the membrane walls faster.

-

Nitrogen molecules move more slowly and remain concentrated on the outlet side.

Purity level: 95% to 99.5%.

Flow rate: Suitable for continuous medium-purity demand.

Lifespan: About 5–8 years, but membranes slowly lose performance over time.

Best industries: Food packaging, beverage bottling, breweries, marine shipping, offshore oil and gas platforms, and chemical terminals.

Factors That Control Lifespan:

The actual lifespan of both PSA and membrane nitrogen generators depends on several key factors:

-

Feed air quality – Oil, dust, and moisture shorten the life of CMS and membranes. High-efficiency filters and clean compressed air are critical.

-

Operating conditions – Frequent start/stop cycles and overloading reduce system life. Stable operation extends service.

-

Maintenance schedule – Changing filters, checking the gas path, and servicing air compressors on time prevent early failure.

-

Application demand – Higher purity levels and higher flow rates increase system stress and reduce longevity.

PSA vs Membrane: At a Glance

| Dimension | PSA Nitrogen Generator | Membrane Nitrogen Generator |

|---|---|---|

| Lifespan | 5–8 years, longer with CMS care | 5–8 years, gradual performance drop |

| Purity Level | 95%–99.999% | 95%–99.5% |

| Flow Rate | Small to very large, scalable | Medium, continuous flow |

| Maintenance | Needs filter replacement, clean air | Simple, low maintenance |

| Size & Weight | Larger, heavier system | Compact, lightweight system |

| Energy Use | Lower compressed air consumption | Slightly higher air consumption |

| Industries | Electronics, pharma, chemicals, metals | Food, beverage, marine, chemicals |

The Role of Air Compressors and Cylinders:

Both systems depend on air compressors. Without stable feed air at the right flow rate and pressure, nitrogen generators cannot achieve the required purity. Proper compressor sizing is essential.

Traditionally, many companies used nitrogen cylinders. However, cylinders come with high costs, logistics issues, and safety risks. Deliveries may be late, cylinder rental fees add up, and purity levels may vary. With an on-site nitrogen generation system, businesses replace cylinders with a stable, cost-effective nitrogen supply.

PSA and Membrane in Practice:

When choosing between PSA and membrane nitrogen, consider the following:

-

If your process demands very high purity and stable flow rate, PSA with carbon molecular sieve is the better option.

-

If you need medium purity nitrogen and limited space, a membrane nitrogen generator is easier to install and maintain.

Both PSA and membrane separation systems provide reliable on-site nitrogen generation. They reduce operating costs, improve efficiency, and give companies independence from external nitrogen cylinders.

Modular Nitrogen Systems: A Future Trend:

Modern factories often need flexible production. That’s why modular nitrogen generation systems are growing in popularity. These systems combine PSA and membrane features into one design:

-

Scalable – Add modules to increase flow rate as demand grows.

-

Flexible – Use membrane nitrogen for simple jobs and PSA nitrogen for high-purity tasks.

-

Reliable – Reduce downtime compared to depending on bulk deliveries or cylinders.

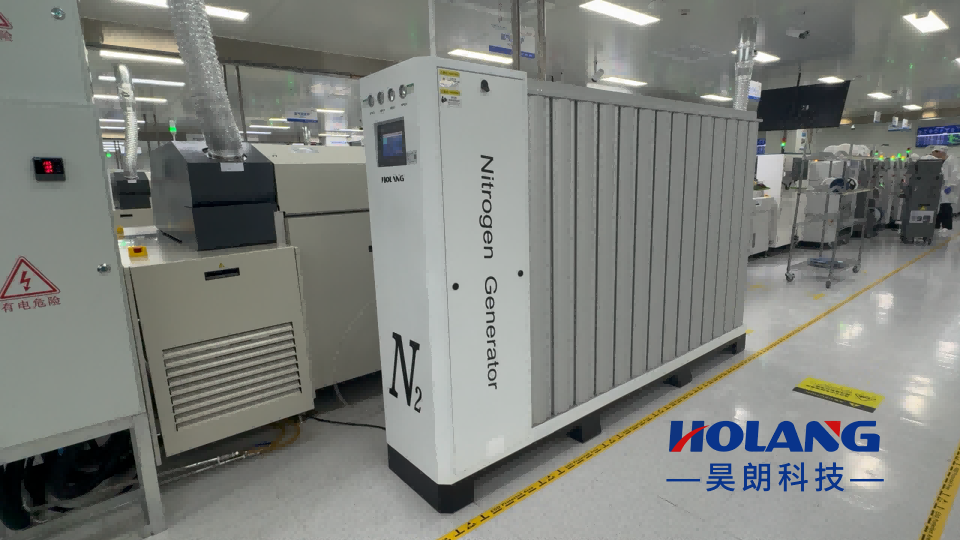

HOLANG Tech (Suzhou) Co., Ltd. has introduced modular nitrogen generation systems since 2017. With over 1,000 systems installed in more than 50 countries, HOLANG serves industries from electronics to food, chemicals, and energy.

Conclusion:

There is no absolute winner in the PSA vs membrane debate. The choice depends on your purity level needs, flow rate requirements, available space, and energy cost targets.

-

PSA nitrogen generators: High purity, long lifespan, energy-efficient.

-

Membrane nitrogen generators: Simple, compact, good for medium purity.

Both methods allow companies to secure nitrogen supply on-site, cut costs, and reduce dependence on nitrogen cylinders.