When companies consider switching from delivered cylinders or bulk liquid nitrogen to on-site gas generation, one of the first questions asked is simple: What is the real nitrogen generator cost? The investment in gas generators can feel significant at first glance, but the long-term savings and reliability are often far greater than most managers expect. This article answers the most common questions about PSA and membrane nitrogen generation systems, explains cost factors, and shows how to evaluate the right solution for your application.

1. What determines nitrogen generator cost?

Several factors affect the cost of a nitrogen generation system:

-

Technology type: PSA (Pressure Swing Adsorption) vs. membrane. PSA typically requires a higher upfront investment due to the use of Carbon Molecular Sieves (CMS) and dual-tower design.

-

Nitrogen purity level: The higher the required purity, the more energy and feed air are needed, and the higher the capital cost. For example, generating nitrogen at 99.999% requires larger vessels and more sophisticated controls than producing 95%.

-

Flow of nitrogen: A system designed to deliver 5 Nm³/h costs much less than one engineered for 200 Nm³/h. Flow requirements directly influence compressor size, buffer tanks, and filters.

-

Pressure requirements: Some processes need high pressure nitrogen delivery. This may add booster compressors or reinforced vessels, which increase both capital and operating expenses.

-

Supporting equipment: The nitrogen generator does not operate alone. Feed air must be properly conditioned with dryers, filters, and storage receivers. These components are essential to protect the system from water vapor and oil contamination.

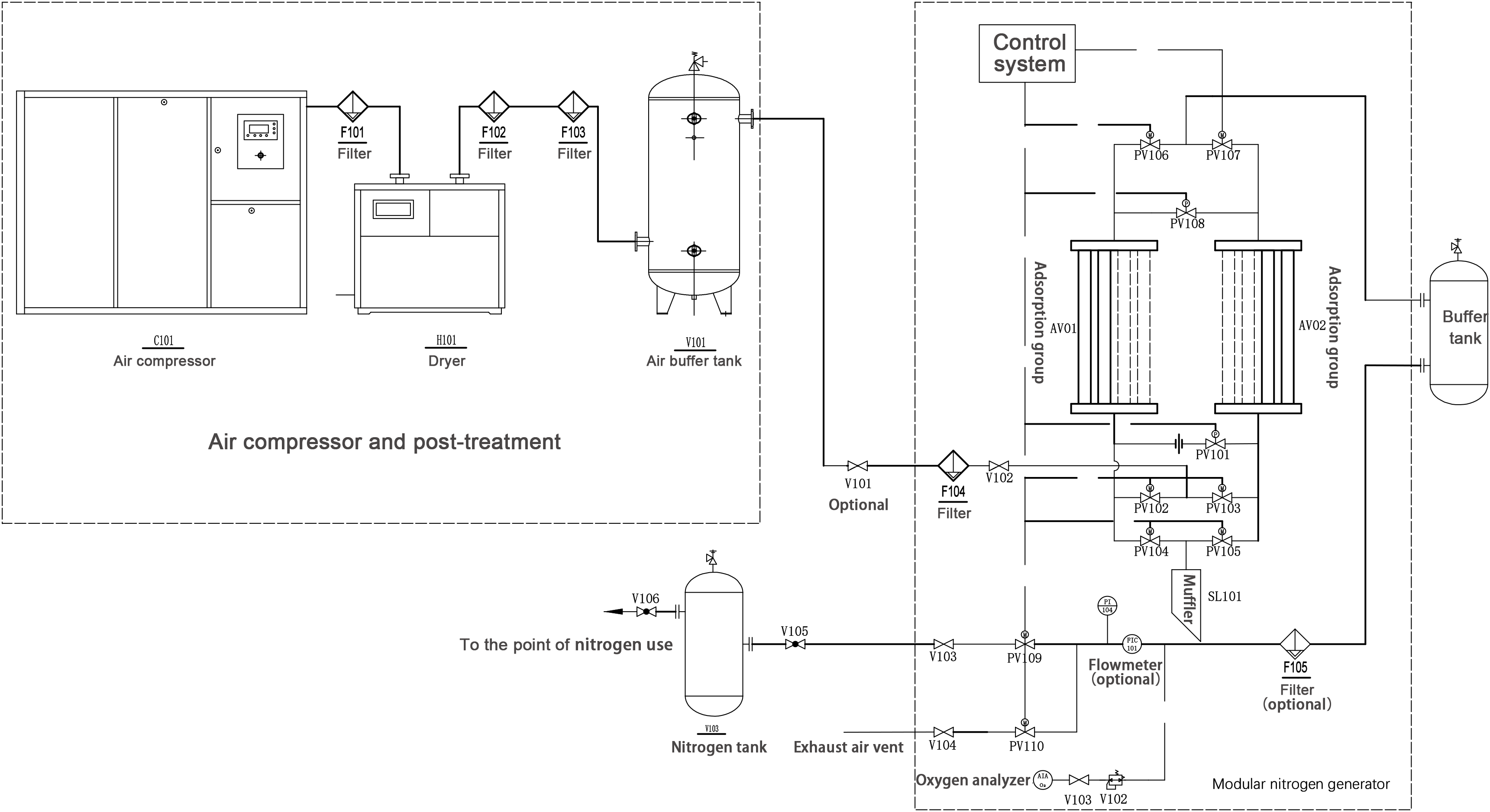

2. How does a PSA nitrogen generator work?

PSA technology is based on adsorption. Compressed feed air enters a tower filled with Carbon Molecular Sieves. Molecules such as oxygen, water vapor, and carbon dioxide are adsorbed, while nitrogen molecules pass through as the product gas. Two towers alternate between adsorption and regeneration, allowing continuous nitrogen production.

-

Purity range: From 95% up to 99.999%.

-

Flow stability: Output may fluctuate slightly during tower switching.

-

Best suited for: Laboratories, pharmaceuticals, food packaging, and electronics manufacturing where high nitrogen purity levels are critical.

3. How does a membrane nitrogen generator work?

Membrane technology uses selective permeation. When compressed air passes through hollow fiber membranes, oxygen and water vapor molecules travel faster through the membrane walls than nitrogen molecules. As a result, nitrogen is concentrated and delivered as the product gas.

-

Purity range: Typically 90–99.9%.

-

Flow stability: Very stable, no switching cycles.

-

Best suited for: Oil and gas fields, fire prevention, tire inflation, and packaging applications where moderate nitrogen purity is sufficient.

4. What are the ongoing costs of generating nitrogen on-site?

The main operating costs are related to electricity for the air compressor and periodic maintenance of filters and valves. Compared with nitrogen cylinders or bulk deliveries, the savings are significant:

-

Nitrogen cylinders: Require constant reordering, storage space, handling labor, and rental fees. The cost per unit of gas can be four to five times higher than on-site generation.

-

Bulk liquid nitrogen: Lower per-unit price than cylinders but still includes delivery fees, tank rental, and boil-off losses.

-

On-site gas generators: Once installed, the net nitrogen generator cost is mainly electricity. Depending on the system efficiency and local energy prices, the cost per cubic meter of nitrogen can drop by more than 50%.

5. How long until the system pays for itself?

Most nitrogen generation systems pay back within 12–24 months. For high-demand users such as food packaging plants or laboratories running LC-MS and GC instruments 24/7, the payback can be even faster. After the initial return on investment, the generator provides nearly free nitrogen for many years.

6. How does water vapor affect nitrogen production?

Clean and dry feed air is essential. If water vapor or oil aerosols enter the nitrogen generation system, they can damage the Carbon Molecular Sieves or the membrane fibers. For this reason, a complete installation always includes:

-

Refrigerant or desiccant dryers

-

Oil coalescing filters

-

Activated carbon filters

Maintaining the correct pressure dew point ensures reliable performance and long service life of the generator.

7. What about reliability and service life?

Modern PSA and membrane generators are built to last. With proper maintenance—typically annual service for filters and routine checks—a nitrogen generation system can operate for 10 years or more. They are chemically inert, resistant to vibration and shocks, and provide continuous nitrogen production independent of outside deliveries.

8. What are the disadvantages?

No system is perfect.

-

Capital investment: Higher upfront cost compared with renting nitrogen cylinders.

-

Purity vs. flow trade-off: In PSA systems, higher nitrogen purity levels reduce maximum flow of nitrogen. High purity at high flow requires larger and more expensive gas generators.

-

Energy dependence: On-site generation relies on electricity. Facilities should ensure stable power supply or backup solutions.

Despite these limitations, the long-term economics strongly favor generating nitrogen on-site rather than relying on deliveries.

9. How do I choose the right nitrogen generation system?

Start with three questions:

-

What nitrogen purity level is required by your process?

-

How much flow of nitrogen is needed per hour?

-

At what pressure should the gas be delivered?

Once these are defined, a system can be sized correctly. For high purity applications, PSA nitrogen generators are usually recommended. For moderate purity, especially where mobility or simplicity is important, membrane nitrogen generators provide excellent performance.

Conclusion

Understanding nitrogen generator cost requires looking beyond the purchase price. By evaluating total cost of ownership—including feed air treatment, maintenance, and energy consumption—companies often realize that on-site nitrogen production is far more economical than cylinders or bulk supply.

Whether you choose a PSA nitrogen generator for ultra-high nitrogen purity or a membrane nitrogen generator for low-maintenance operation, the result is the same: independence from cylinder deliveries, control over gas supply, and significant cost savings.

On-site nitrogen generation has become the standard for industries ranging from food and beverage to pharmaceuticals, electronics, and oil & gas. With the right nitrogen generation system in place, your company gains reliable, efficient, and cost-effective nitrogen for the long term.

How to Choose the Right Model?

The right nitrogen generator depends on your purity and flow needs.

-

For laboratories and ultra-high purity applications (99.99%+), our NPL Series PSA Nitrogen Generators deliver stable performance up to 99.999%.

-

For food packaging and general manufacturing with mid-level purity, the NPA Series PSA Nitrogen Generators provide a cost-effective solution.

-

For oil & gas, tire inflation, or fire prevention, our NMA Series Membrane Nitrogen Generators offer simplicity and mobility.

👉 Explore the full range of HOLANG nitrogen generation systems. For more model options, please visit our product section.

Contact Us

Need help choosing a nitrogen generator or want a quotation? Our team is ready to support you.

📧 Email: marketing@holangchina.com

📞 Phone: 400-0512-711

🏢 Address: No. 51, Jinsigang Road, Wuzhong District, Suzhou, Jiangsu, China