Electronics manufacturing is becoming more advanced every year. Smaller components, higher levels of integration, and stricter quality demands make yield a critical factor in production. Companies often focus on adjusting the soldering process, changing solder paste, or fine-tuning reflow curves, but many overlook one key variable: the purity of nitrogen used in the production line.

This article explains why PSA nitrogen generators, membrane technologies, and other nitrogen gas generators are now essential for modern electronics factories. It also looks at how purity levels affect the wave soldering process, the cost advantages of on-site nitrogen production, and why a cost-effective nitrogen gas supply improves both quality and long-term savings.

Why Electronics Manufacturing Needs Pure Nitrogen?

-

Prevent oxidation

Oxidation is the number one risk during reflow and wave soldering. Without high purity nitrogen, solder joints can form oxide layers that lead to weak connections or complete failure. -

Improve soldering process results

When nitrogen purity is high, solder spreads more evenly, joints look smoother, and defects such as solder balls or bridging are reduced. -

Protect sensitive devices

Chips, connectors, and metallic contacts last longer when protected by pure nitrogen. Reliability increases, and fewer units fail during testing.

Purity Levels and Yield

-

95%–99% nitrogen: Common in industry nitrogen applications like metal processing or food packaging. Not enough for high-end electronics.

-

99.9% nitrogen: Improves yield and reduces common defects. Considered the entry-level standard for electronics.

-

99.999% nitrogen (five nines): Now the mainstream requirement for advanced SMT, BGA, and CSP assembly lines.

📊 Studies show that moving from 99.9% to 99.999% nitrogen purity raises yields by 3%–8%. On a high-volume line, that means tens of thousands fewer defective boards per month and significant cost savings.

Why On-Site Nitrogen Gas Generators Are Cost-Effective?

Buying liquid nitrogen and cylinders has always been expensive. Deliveries also carry risk—weather, logistics, or policy changes can disrupt the supply chain. If a line loses nitrogen gas supply, production stops, and the financial loss can be massive.

Installing on-site nitrogen gas generators solves this problem:

-

Upfront cost vs. long-term savings: A generator requires investment, but the payback period is usually short compared to the constant expense of bulk liquid nitrogen.

-

Flexibility: PSA and membrane technologies allow operators to adjust flow and purity level as required by the production line.

-

Stability: No more relying on deliveries; nitrogen is produced directly from compressed air using your own air compressor.

PSA Nitrogen Generators: Pressure Swing Adsorption:

PSA nitrogen generators are the most popular choice for high-purity applications. Using pressure swing adsorption (PSA) technology, these systems separate nitrogen from oxygen with the help of carbon molecular sieve.

-

Process: Feed air from an air compressor enters two towers. Oxygen molecules are adsorbed by the sieve, while nitrogen passes through. The towers switch cycles to maintain continuous production.

-

Purity level: Up to 99.999% high purity nitrogen.

-

Applications: SMT soldering, semiconductor packaging, wave soldering, metal heat treatment, and chemical protection.

-

Service life: 5–8 years or more with proper care and clean feed air.

Membrane Technologies: Simple and Flexible:

Membrane nitrogen generators use hollow fibers that let gases pass at different speeds. Oxygen, CO₂, and water vapor permeate quickly, while nitrogen flows more slowly and becomes concentrated.

-

Purity level: 95%–99.5%, suitable for medium-level purity needs.

-

Applications: Food packaging, beverage filling, shipping, and general industry nitrogen use.

-

Advantages: Low maintenance, smaller footprint, quick startup.

-

Limitations: Not ideal for ultra-high purity soldering processes.

PSA and Membrane Compared:

|

Dimension |

PSA Nitrogen Generators |

Membrane Technologies |

|---|---|---|

|

Purity Level |

95%–99.999% |

95%–99.5% |

|

Best Use |

High purity soldering process, CSP, BGA, SMT |

Medium-purity industry nitrogen, packaging |

|

Cost Savings |

Strong over time despite higher upfront cost |

Lower initial investment, but limited purity |

|

Maintenance |

Requires filter changes, clean feed air |

Minimal, simple service |

|

Space Requirement |

Larger, heavier systems |

Compact, lightweight |

|

Nitrogen Production |

Stable long-term supply with air compressor input |

Flexible, lower purity continuous supply |

Real Benefits in Electronics Manufacturing:

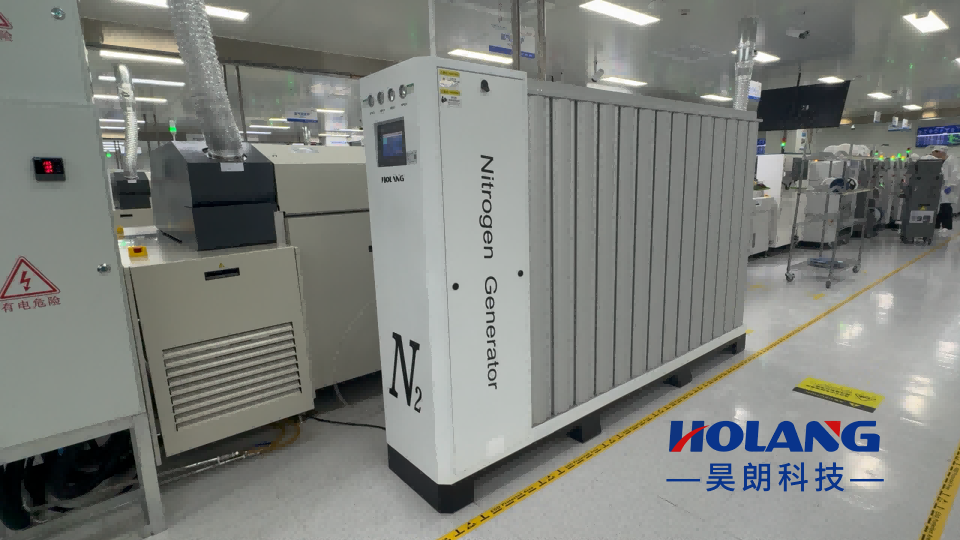

A leading electronics company in Sichuan has used HOLANG’s PSA nitrogen gas generators for more than three years. By upgrading to on-site nitrogen production, the company improved its yield by more than 5%, reduced rework rates, and cut costs associated with buying and storing cylinders. The systems have been reliable, producing pure nitrogen 24/7 without interruption.

HOLANG Solutions:

HOLANG Tech (Suzhou) Co., Ltd provides advanced nitrogen generation systems tailored for the electronics industry:

-

NPL Series: Modular PSA nitrogen generators capable of 95%–99.999% purity.

-

Flexible design: Modular expansion to match production growth.

-

Smart operation: Touch screens track purity and flow, with alarms for safety.

-

Continuous supply: 24/7 nitrogen production directly from feed air.

These systems are trusted by electronics manufacturers for their ability to provide high purity nitrogen that directly improves yield and reduces costs.

Conclusion:

The link between nitrogen purity and yield is clear. For high-tech electronics, high purity nitrogen is no longer optional—it is essential.

-

PSA nitrogen generators with pressure swing adsorption deliver ultra-pure nitrogen needed for modern soldering processes like SMT and wave soldering.

-

Membrane technologies provide a cost-effective solution for general industry nitrogen needs.

By investing in on-site nitrogen production, companies gain a stable, cost-effective nitrogen gas supply, reduce dependence on cylinders, and achieve long-term cost savings.

HOLANG remains dedicated to delivering efficient, reliable, and scalable nitrogen gas generators for the electronics industry and beyond.