Nitrogen is a colorless, odorless, non-toxic inert gas that is cost-effective to produce and highly efficient. As a result, nitrogen is widely used across numerous industries. With the advancement of science and technology and the ongoing development of economic infrastructure, nitrogen’s applications have become increasingly widespread, extending into many industrial sectors and everyday life. Below, HOLANG Technology provides a brief overview of how nitrogen is utilized in different industries.

1. Metallurgy and Metal Processing

Nitrogen is extensively used in the metal industry. In heat treatment processes, nitrogen-based atmospheres are a safe, environmentally friendly, and energy-saving alternative. It is recognized that nearly all heat treatment methods—such as carburizing, nitriding, normalizing, tempering, bright annealing, spheroidizing, and recrystallization annealing—can be carried out using nitrogen-based atmospheres. Treated metal parts exhibit comparable quality and appearance to those processed with traditional endothermic gas atmospheres.

2. Petrochemical Industry

In the chemical industry, nitrogen is widely applied for raw material gas blanketing, pipeline purging, atmosphere replacement, inert protection, and product transportation. In the petroleum sector, nitrogen helps optimize refining processes, pressurize oil and gas wells, clean and purge pipelines, and assist in solvent recovery.

3. Pharmaceutical Industry

After sterilization, dust removal, and moisture removal, nitrogen meets the stringent requirements of the pharmaceutical industry. It is used in drug packaging, as a replacement gas, in nitrogen-flushed packaging, and during transportation. It also helps protect herbal medicines from pests and spoilage, and supports scientific research and cryogenic treatments.

4. Food & Fresh Produce

Nitrogen is commonly used to store and preserve fruits, vegetables, and tea leaves. A high-nitrogen, low-oxygen environment slows metabolism and inhibits ripening, which in turn reduces spoilage and oxidation. Nitrogen-filled packaging maintains the shape, dryness, crispness, color, aroma, and flavor of food. In beverage production, nitrogen not only helps with freshness and storage but also improves the taste of beer and soft drinks.

5. Electronics Industry

Nitrogen plays a critical role in the electronics sector. It is indispensable in processes such as packaging, sintering, annealing, reduction, and storage of electronic components. It is widely used in wave soldering, reflow soldering, crystal components, piezoelectric devices, electronic ceramics, copper strips, batteries, and electronic alloys. High-purity nitrogen (99.99% or 99.999%) is often required. Nitrogen is essential for protective atmospheres, cleaning, and chemical recovery in the production of semiconductors and integrated circuits. In China, high-purity nitrogen is now commonly used in the manufacturing of CRT displays, large-scale ICs, LCDs, and semiconductor wafers.

6. Marine Industry

In the marine industry, nitrogen is used to drive dry powder and halon fire suppression systems. It also serves as a sealing blanket gas to prevent fuel degradation, and for inerting cargo holds—preventing explosions and maintaining cargo quality.

7. Analytical Laboratories

In laboratories, nitrogen is used for purging, gas supply, and pressure maintenance for lab instruments. Being inert, nitrogen prevents contamination and oxidation of sensitive experimental materials during testing.

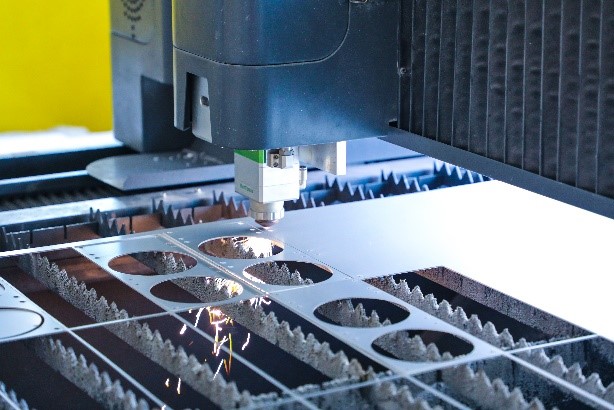

8. Laser Cutting

Nitrogen solves many challenges in laser processing and expands the scope beyond what oxygen cutting can handle. During nitrogen cutting, materials are melted purely by laser energy. The inert nitrogen prevents undesired chemical reactions and improves the quality of the cut. Nitrogen also provides cooling and protection, resulting in smooth, clean edges without the oxidation layer typically formed during oxygen cutting.

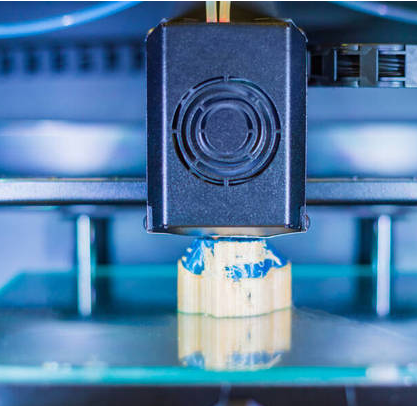

9. 3D Printing

Nitrogen is an economical, readily available, and chemically stable gas, making it crucial in metal 3D printing applications. These printers often require sealed chambers to prevent the release of harmful byproducts and eliminate oxygen interference. Nitrogen effectively meets this need, serving as a circulation gas within the sealed chamber. For oxygen-sensitive materials, nitrogen provides protective conditions to ensure product integrity.

HOLANG’s modular nitrogen generators provide safe, efficient, and cost-effective on-demand nitrogen solutions for a wide range of applications, tailored to the specific needs of different customers. With reliable performance, easy integration, and a flexible, scalable design, HOLANG nitrogen systems help businesses improve productivity, ensure operational safety, and significantly reduce long-term operating costs. Choose HOLANG and empower your industry with smarter nitrogen solutions.