🌍 Nitrogen Generators in Modern Industry

In today’s industrial world, nitrogen generators are widely used across various sectors to meet nitrogen demands. Whether in electronics manufacturing, food packaging, petrochemicals, aerospace, or biopharmaceuticals, high-quality nitrogen is essential.

This article explores the fundamental working principles of nitrogen generators, their applications in the biopharmaceutical industry, and key considerations when selecting a suitable unit.

⚙️ What Is a Nitrogen Generator?

A nitrogen generator is a device that separates nitrogen from ambient air using physical or chemical methods.

The most common technologies are:

-

Pressure Swing Adsorption (PSA):

Uses clean compressed air and carbon molecular sieves. Through pressurized adsorption and depressurized desorption, it separates nitrogen and oxygen to produce nitrogen of desired purity.

-

Membrane Separation:

Utilizes different permeation rates of gases through a polymer membrane to achieve gas separation.

💊 Applications in the Biopharmaceutical Industry

Nitrogen generators play an important role in the biopharma sector. Common applications include:

● Pharmaceutical Production

Used to create an inert atmosphere that prevents oxidation. It also protects sensitive drug ingredients from moisture and oxygen contamination.

● Drug Packaging and Preservation

Nitrogen is commonly used in pharmaceutical packaging to eliminate oxygen and maintain drug stability and efficacy, thereby extending shelf life. Typical applications include biologics, oxygen-sensitive drugs, and sterile products.

● Laboratory and Research

High-purity nitrogen is used as a carrier or shielding gas to ensure accuracy and repeatability in experiments. Nitrogen generators support drug synthesis, drying, storage, and are compatible with instruments like gas chromatographs and mass spectrometers.

● Medical Equipment

Nitrogen is used in drying and cleaning during medical device manufacturing. It also supplies nitrogen to equipment such as anesthesia machines and ventilators.

● Other Medical Applications

Used in surgical anesthesia and hemostasis, dental anesthesia and root canal treatment, and dermatology for cryotherapy and acne treatment.

🧩 What to Consider When Choosing a Nitrogen Generator?

When selecting a nitrogen generator for pharmaceutical applications, consider the following:

-

Required nitrogen purity

-

Desired flow rate

-

Stability and reliability of the system

-

Compliance with industry standards and regulations

-

Ability to meet scalable demand

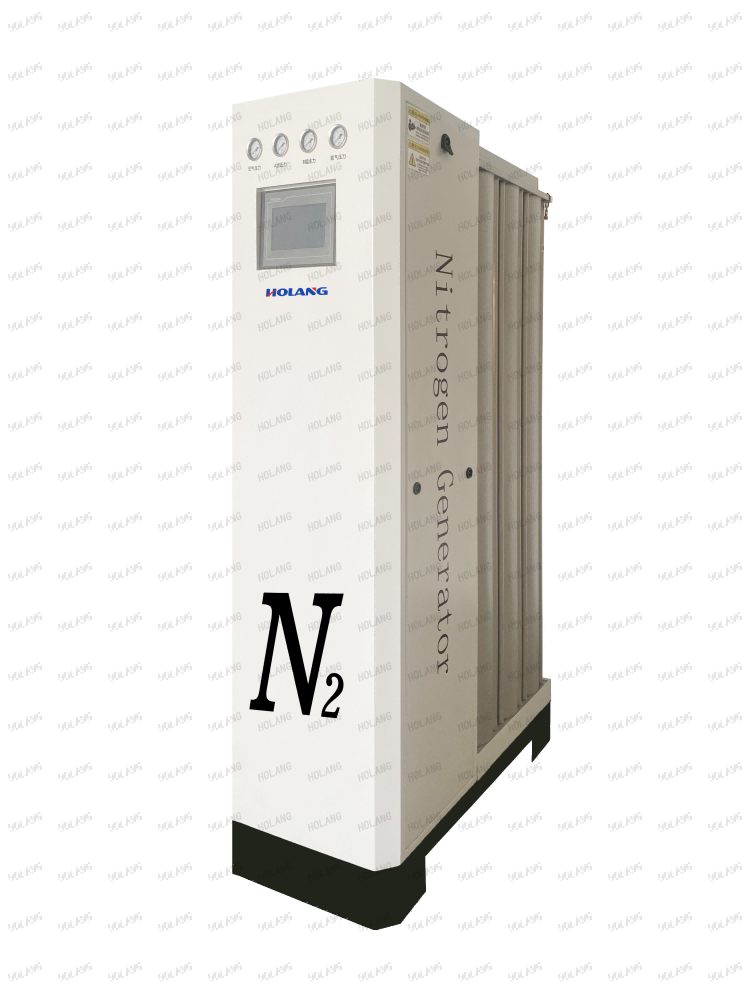

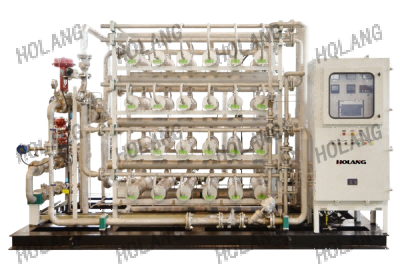

🔧 HOLANG Technology – A Professional Nitrogen Solution Provider

HOLANG Technology (Suzhou) Energy Technology Co., Ltd. is an innovative company focused on industrial gas solutions, offering nitrogen generators and customized gas supply systems tailored to various industries.

💡 Advantages of HOLANG Nitrogen Generators

-

On-site nitrogen generation avoids safety risks from high-pressure cylinders and cryogenic tanks.

-

Continuous and cost-efficient nitrogen supply, eliminating the need for refills and external vendors, lowering long-term operating costs.

-

Energy-saving mode with adjustable purity and flow rates to reduce energy consumption.

-

Modular design with a compact footprint and easy installation.

-

Standardized adsorption modules made from precision aluminum alloy for durability and corrosion resistance.

-

Expandable system design with removable and replaceable modules that reduce maintenance costs without affecting overall performance.

-

Smart touchscreen control panel with high automation and user-friendly operation.

-

Closed-loop monitoring of pressure, flow, and purity with alarms and safety valves to ensure secure operation.

-

Maximum use of quick-connect fittings for easy maintenance and repairs.