Карьера

"High Purity Nitrogen Gas: Guarding the 'Breathing Code' of Life Sciences"

— Unveiling the "Invisible Guardian" in the Biopharmaceutical Industry

In biopharmaceuticals, every microgram of sample viability and every milliliter of reagent stability impacts human health:

🧫 Cell Culture: Oxygen fluctuations disrupt cellular metabolism

💊 Lyophilized Formulations: Moisture residues trigger drug denaturation

🔬 Mass Spectrometry: Environmental contaminants compromise accuracy & equipment lifespan

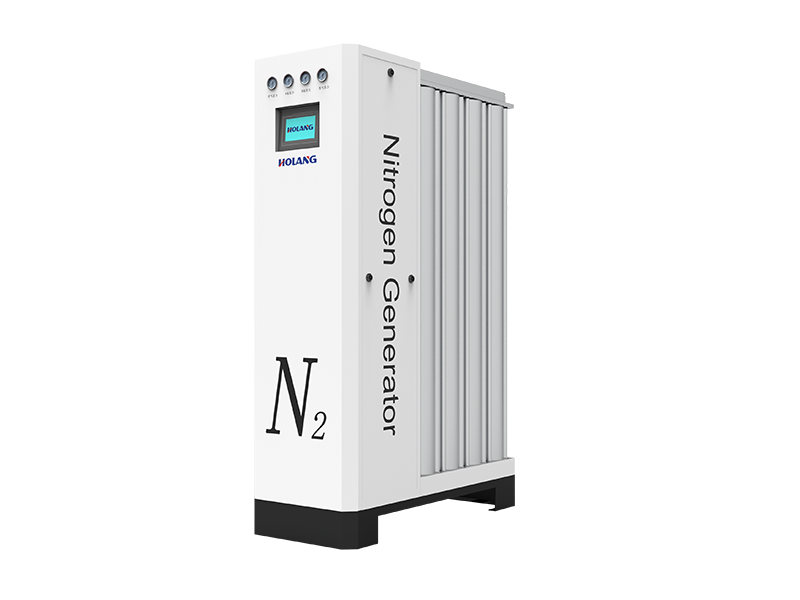

Nitrogen Generators: The Master Key to Precision:

Delivering 99.999% ultra-pure nitrogen to create an oxygen-free, anhydrous, sterile barrier across R&D, production, and storage.

In biotechnological processes, cell culture, vaccine production, and other biopharmaceutical preparations, nitrogen is used to create an anaerobic or low-oxygen environment, protecting sensitive biological materials from oxidation while preventing microbial growth, ensuring the quality and safety of biological products.

During pharmaceutical production, nitrogen, as an inert gas, prevents drug components from oxidizing, protects reactors, and improves the stability and efficacy of drugs. During packaging, filling with high-purity nitrogen delays drug degradation and extends shelf life, which is particularly crucial for oxygen-sensitive drugs like vitamins and antibiotics.

In pharmaceutical laboratories, nitrogen is used to clean and purge equipment, removing potential contaminants. High-purity nitrogen is also used to handle samples before gas chromatography-mass spectrometry (GC-MS) analysis, ensuring the accuracy of results.

Some medical devices require nitrogen for cleaning, drying, or as a driving gas. Nitrogen purification systems provide stable, high-purity nitrogen to ensure the proper functioning and prolonged lifespan of medical equipment.

For oxygen-sensitive pharmaceutical products, such as active pharmaceutical ingredients (APIs) and other chemicals, nitrogen is used as a purging gas during packaging to prevent oxidation and degradation. During transport, nitrogen helps maintain the sterility and cleanliness of products, ensuring their stability and safety.

(Comparison Table: Red/Green Alert Style)

| Gas Cylinders | Holang Modular Generator |

|---|---|

| Purity fluctuation (85%-99.9%) | 95%-99.999% adjustable |

| Supply interruptions, gas exchange, transportation risks | 24/7 continuous flow |

| Annual maintenance costs >100,000 CNY | 55% energy saving, ROI in 3 years |

| High-pressure storage hazards | Modular design, on-site nitrogen generation, small footprint, safe and reliable |

🔬 Technical Superiority:

High-quality carbon molecular sieve intelligent regeneration system

Built-in oxygen analyzer for real-time oxygen content monitoring, ensuring continuous stable anaerobic conditions

Triple filtration system with particulate matter ≤ 0.01μm

International ISO quality certification and CE certification

"Nitrogen is not merely a gas flow—it's the invisible hand shielding life's vital spark."

Holang Technology delivers military-grade precision for medical nitrogen solutions,ensuring every breath of innovation sustains hope.

Act Now for Your Pharmaceutical-Grade Nitrogen Solution

Hotline: +86 400 0512 711