Карьера

— From Chip Packaging to Precision Welding: How Stable Nitrogen Supply Empowers Smart Manufacturing Upgrades

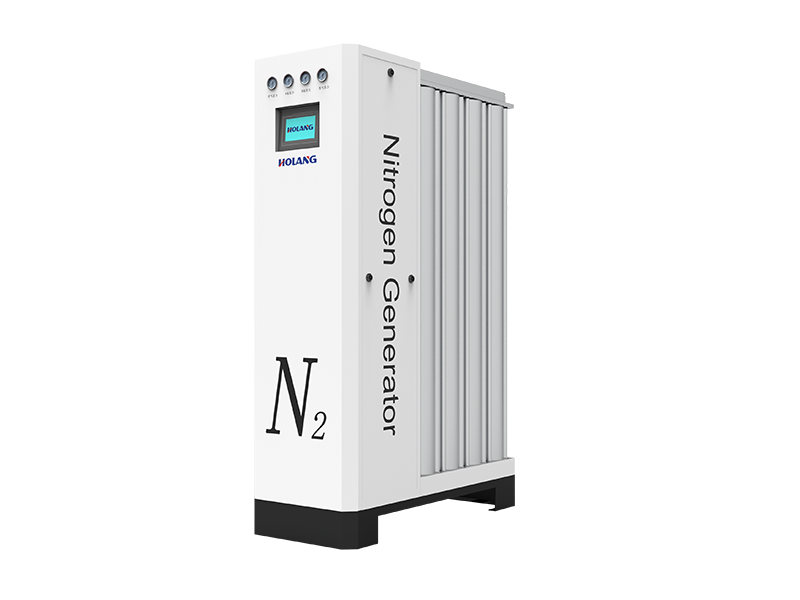

Nitrogen generators, with their high purity, safety, reliability, and cost-effectiveness, have become indispensable equipment in modern electronics manufacturing. As 5G communications, IoT, and new energy technologies rapidly advance, their application scenarios continue to expand.

Oxygen-Free Welding Protection

Pain Point: Oxygen exposure during electronic component soldering causes oxidation and weak joints, reducing yield rates.

Solution: Nitrogen generators deliver 99.99% high-purity nitrogen to create localized oxygen-free environments, ensuring smooth and reliable soldering.

Applications: SMT reflow soldering, BGA packaging, precision PCB welding.

Chip Packaging & Storage

Pain Point: Chips are highly sensitive to humidity and oxidation, while traditional liquid nitrogen tanks incur high costs and transportation risks.

Solution: On-site nitrogen generation with constant pressure/flow supply, directly integrated into packaging lines or storage facilities to extend chip lifespan.

Laser Cutting & Precision Machining

Pain Point: Metal/ceramic substrate cutting generates burrs that compromise component performance.

Solution: Nitrogen as auxiliary gas enables rapid cooling and slag removal, enhancing cutting precision and surface finish.

Electronic Component Cleaning & Drying

Pain Point: Residual moisture after solvent cleaning risks circuit shorting.

Solution: High-purity nitrogen purging achieves residue-free drying, compatible with sensitive electronic materials.

Cleanroom Environment Control

Pain Point: Particulates and static electricity damage precision components.

Solution: Nitrogen-positive pressure environments suppress dust ingress while inert properties reduce static accumulation.

| Criteria | Nitrogen Generator | Liquid Nitrogen Tanks/Cylinders |

|---|---|---|

| Purity Stability | Real-time monitoring & adjustment (99.9%~99.999%) | Risk of contamination during transport |

| Cost Efficiency | 1-2 year ROI + long-term savings | High recurring procurement & logistics costs |

| Safety | No pressurized storage, leak-proof design | Cryogenic burns & explosion risks |

| Responsiveness | On-demand production, seamless integration | Supplier-dependent, delays in emergencies |

Ultra-Pure Nitrogen Assurance

PSA/membrane separation technology achieves 99.999% purity, compliant with ISO standards and CE certification.

Smart IoT Control

Built-in flow/pressure/purity sensors enable dynamic monitoring and automatic alerts for safe operations.

Silent & Compact Design

Multi-layer noise reduction (<65dB), 50% smaller footprint, compatible with Class 1K/10K cleanrooms.

Design systems with 20% capacity buffer based on peak gas demand.

Contact us for professional selection advice and customized nitrogen solutions!

"The ultimate pursuit of safety, ease of use, durability, easy maintenance, aesthetics (A-SEED) is the beginning and end of Haolang's original design."

Call to Action:

"Optimize your production line – Get expert nitrogen solutions tailored to your needs!"

Recommended model:NPL

Selective wave soldering is recommended at 99.999% : NPL01-04B

Reflow soldering monorail recommended selection (99.99%):NPL08-11B,Dual-track:NPL11-14B